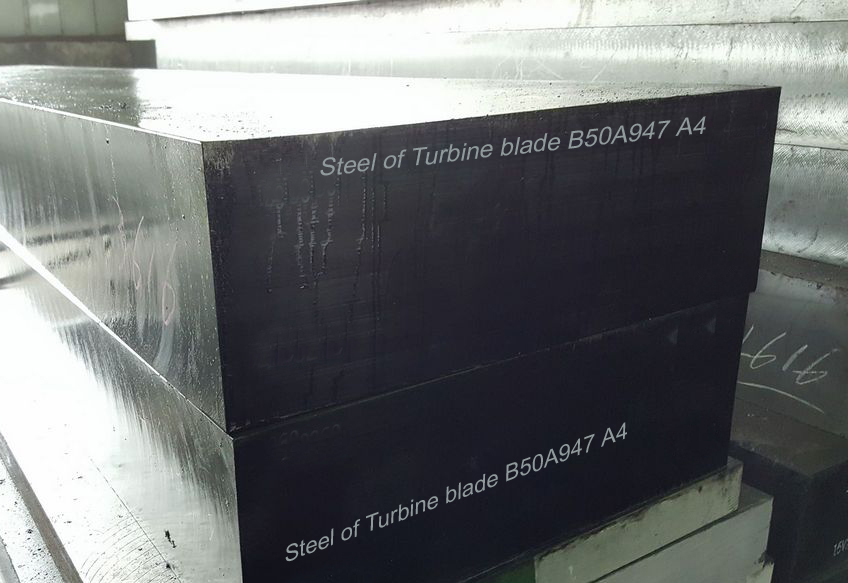

Steel of Turbine blade B50A947 A4

- Smelting Method:

- Delivery status: Forged 、Q+T 、

- Dimensions: □180mm*120mm*L

- Surface: Milling 、

- Standard: Select

Quick Details

By 50 t, 3 LF electric arc furnace smelting furnace t electrode, electroslag remelting, insulation, annealing, 800 650 * 4 mill production process leaves Phi 180 steel refining, casting (%: 0 06 ~ 0 15C, 0 25 ~ 0 80M 11 25 ~ 13 n, 00C R, M o = 0 30, 60N

Stock Status

Product Details

By 50 t, 3 LF electric arc furnace smelting furnace t electrode, electroslag remelting, insulation, annealing, 800 /650 * 4 mill production process leaves Phi 180 steel refining, casting (%: 0.06 ~ 0 15C, 0.25 ~ 0.80M 11.25 ~ 13 n, 00C R, M o = 0.30, 60N = 0 I less than or equal to 0, 025P, 0.010S). The electric furnace smelting ingredients into the dephosphorizing agent, Bachu all LF dross. After refining argon blowing, A line and C a - S I line were finally deoxidized. After analysis, the technical indexes meet the standard requirements

By 50 t, 3 LF electric arc furnace smelting furnace t electrode, electroslag remelting, insulation, annealing, 800 /650 * 4 mill production process leaves Phi 180 steel refining, casting (%: 0.06 ~ 0 15C, 0.25 ~ 0.80M 11.25 ~ 13 n, 00C R, M o = 0.30, 60N = 0 I less than or equal to 0, 025P, 0.010S). The electric furnace smelting ingredients into the dephosphorizing agent, Bachu all LF dross. After refining argon blowing, A line and C a - S I line were finally deoxidized. After analysis, the technical indexes meet the standard requirements